Given the greatest mechanical properties of PVC-O pipes, Molecor Air Based Technology achievement is to supply a highly stable process allowing the highest orientation degree and thus reporting consistent raw material savings with easy transformation of PVC-U lines into PVC-O lines.

Molecor started a novel technological project with the purpose of gathering the greatest advantages from previous systems: an efficient process, highly stable allowing the highest orientation, easy to use and lay-out compatible.

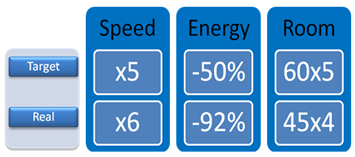

Since the beginning, the system basics were based on the in batch system, mainly due to the stability and the class 500 orientation degree. The main points to be improved were: Speed increase, reduction of energy consumption, space and labor.

The use of air brings many advantages: the process is clean, safe and leakages do not pose a problem. The process with air spares the use of expensive stainless steel or anticorrosive material. The process is faster because the conditioners of air are much faster than the water ones.

Critical technical issues needed to be accomplished: The pipe conditioning, the speed of expansion and fast air chilling.

The pipe had to be heated up homogeneously with extreme accuracy in the three cylinders coordinates: axial, hoop and radial. A special oven is designed with high internal air movement speed, allowing close to a forty renovations per minute. Isolation is attentively considered to prevent heat looses and noise. The prospects of output and homogeneity are up to this point fulfilled.

Whereas the speed of expansion is quite easy to control using water, with air this aspect is more sophisticated. The expansion is executed by communicating tanks of compressed air at higher pressure than the one needed to expand. Initially, the pipe to expand is at atmospheric pressure, and the tanks are at high pressure.

Moreover, the required flow is maintained during the main part of the expansion stage and a constant speed of expansion in guaranteed with electronic regulation, fast answer pressure detectors and servo valves.

Air chilling consists of freezing the pipe from orientation temperature to a temperature below Vicat without water.. Aspects such as speed of flow, geometry of pipes or even air humidity were considered and the results obtained, as shown in graph 2, were used to design the final equipment, optimizing energy consumption and output.

A real machine is built to produce pipes from 160Ø to 400Ø mm and tested in regular production with an extrusion line based on a Cincinnati Argos 93. The mixed used is based on PVC resin from Solvin and Chemson.

The following results are obtained:

Huge savings resulted from constant maintenance of the mold temperature and avoiding the use of water as fluid for the process. The energy for conditioning is only applied to the pipe to be processed. The equipment space is compact. The length of the whole line for manufacturing up to 400 Ø mm can be of 45 m and the width is less than 4 meters. The line is fully automatic, which minimizes the labor needs.

Other positive features were also implemented such as swiftness in mold changing; an operation that now takes less than 1 hour for 2 people. All the technical developments were implemented in a recipe system for the operator to choose the pipe to be produced and all the parameters change automatically to the new conditions.

The global pricing competition and the national PVC-O standardization are making of PVC-O one of the current most attractive investment in the plastic industry. The high quality of the product, in addition to the important raw material savings that can reach 50% and the access to more profitable markets for high pressure applications forecasts a great future for PVC-O pipes.