PVC-O, the most eco-friendly solution for pressure water transportation

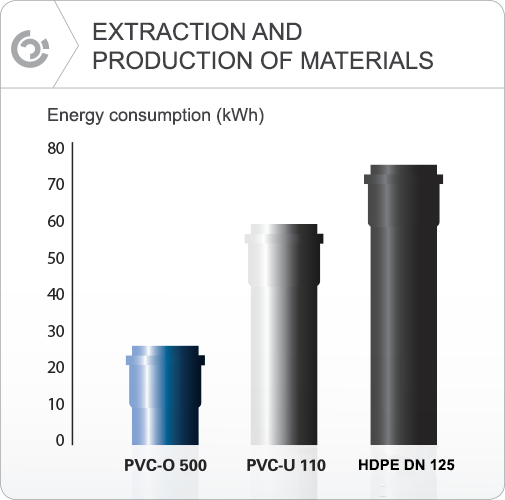

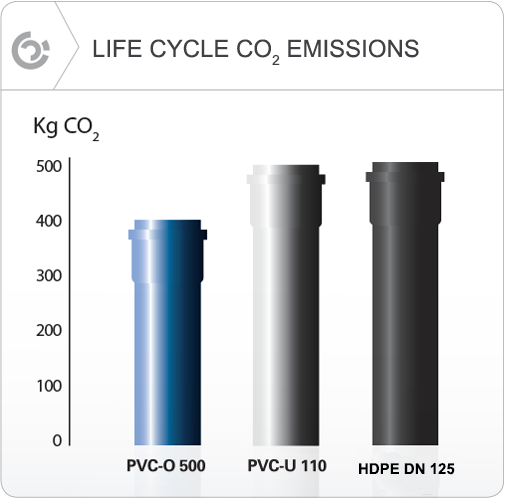

The environmental footprint of PVC-O pipes includes the energy consumption and the CO2 emissions generated throughout the pipes life cycle, such as: extraction and raw material processing, PVC-O pipe production, installation and use, and other subsidiary activities like the transport.

The parameters basically considered relate to the type and amount of raw material used, the energy efficiency during the manufacturing process and the quality of the finished product, and the Molecor PVC-O pipe life expectancy. Therefore, TOM® PVC-O pipes avoid the unnecessary use of energy resources, reducing the CO2 emissions to the atmosphere throughout its useful life.

"ESTIMATION OF ENERGY CONSUMPTION AND CO2 EMISSIONS DUE TO PRODUCTION, USAGE AND FINAL USAGE OF PVC, HDPE, PP AND CAST IRON PIPES". Department of Engineering Proyects. Universitat Politecnica de Catalunya. Barcelona, December 2005. Requested by Foro Iberico del PVC.

"ESTIMATION OF ENERGY CONSUMPTION AND CO2 EMISSIONS DUE TO PRODUCTION, USAGE AND FINAL USAGE OF PVC, HDPE, PP AND CAST IRON PIPES". Department of Engineering Proyects. Universitat Politecnica de Catalunya. Barcelona, December 2005. Requested by Foro Iberico del PVC.