Molecor is a machinery manufacturer that integrates the concept of remote assistance and surveillance for technical support and quality control of the customer's production process.

As an international leading company in the molecular orientation of PVC, Molecor provides comprehensive support to its customer’s business through the latest available technology, as a result of the continuous R & D process with individual and monitored projects.

In the field of automation, Molecor has examined the most advanced standard tools to develop a unique system of remote dialogue.

The system requirements to meet the needs of remote real-time assistance and quality product monitoring demand a solution that enables the access to the information about the general conditions of the equipment. Furthermore, it is necessary to track in detail its operation so as to be able to adjust the parameter settings in remote, to support the implementation in its initial state. In short, to stay connected to the production process.

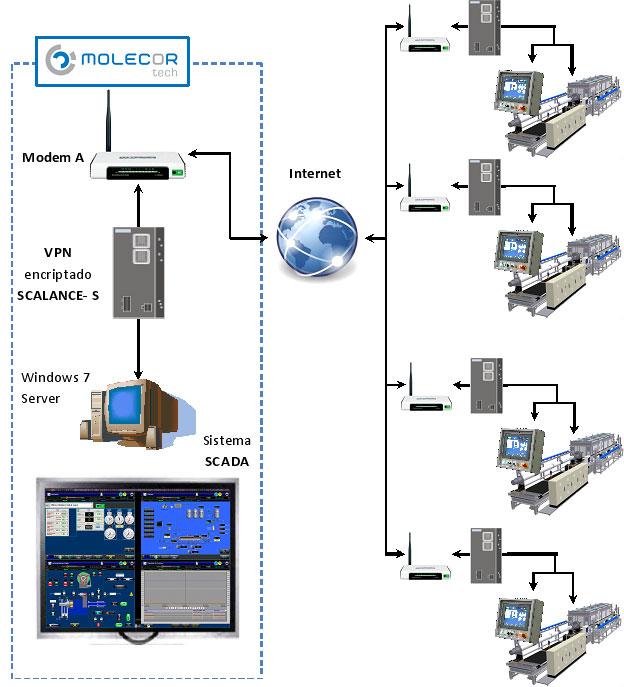

The technical solution, carried out in collaboration with Siemens, is based on a VPN communication, an independent and encoded channel, establishing a secure communication over Internet that permits the connection to the network of machines in operation worldwide through a centralized terminal.

The global business support offered by Molecor places at the client’s disposition its knowledge and technical service, providing high quality equipment for the manufacturing of PVC-O pipes.

Since the standard concept, the remote surveillance system has evolved to become a pioneer solution in the industrial automation.

MOLECOR AFTER-SALES PLATFORM EVOLUTION

Standard communication system VPN LAN2LAN.

It is a structure LAN2LAN that enables VPN users (Molecor equipment users), access via a public IP to the Molecor IPsec tunnel through the Internet. Speed tunneling is dependent on the VPN speed network. It is a transparent system, separated from the IP technology used for the equipment itself, but at the same time a secure network, independent from the customer’s network, which is an additional guarantee for the client.

Remote graphic display of the program with a specific application developed by Molecor.

Thanks to the system developed by Molecor, it is possible to monitor the status of remote machines, similarly as it would be displayed to an operator on-site on the PLC terminal of the machine. This makes it possible to diagnose any malfunction in the process and give support for possible faults in real-time.

Graphic machine application for remote parameter settings exclusively developed by Molecor

Simultaneously implemented with the previous step, the possibility of displaying the control screen of the machine is completed with the traffic flowing in both directions, which permits to load new programming information from the panel if necessary.

Change of structure in the information reception at Molecor, from a terminal to a server.

The complexity of the structure to manage the information is ever increasing, which calls for internal changes in the system, processing as many virtual machines as machines are monitored instantaneously through a Windows 7 server.

Continuous development of specific applications for the customer needs.

Production tracking, process graphics or helpdesk for production and maintenance are some of the applications currently available in the system. The latest one is an online dialogue via short and instant messages between the operator and Molecor technicians.

Molecor full business support implies an asset of technical knowledge and services that defines it as a high quality equipment supplier for PVC-O pipe production.