PVC-O gathers a series of characteristics that make this material optimal for pipe manufacturing and, as we will see, pipes made of this material present extreme advantages and savings for pipe manufacturers, as well as large benefits for potential pipe customers and end users.

Among the characteristics of PVC-O we find:

Unbeatable impact resistance

The application of molecular orientation to PVC improves all the mechanical properties of this material without exception. With this orientation PVC-O becomes a highly resistant material for manufacturing PVC-O pipes which cannot be easily destroyed by regular impacts.

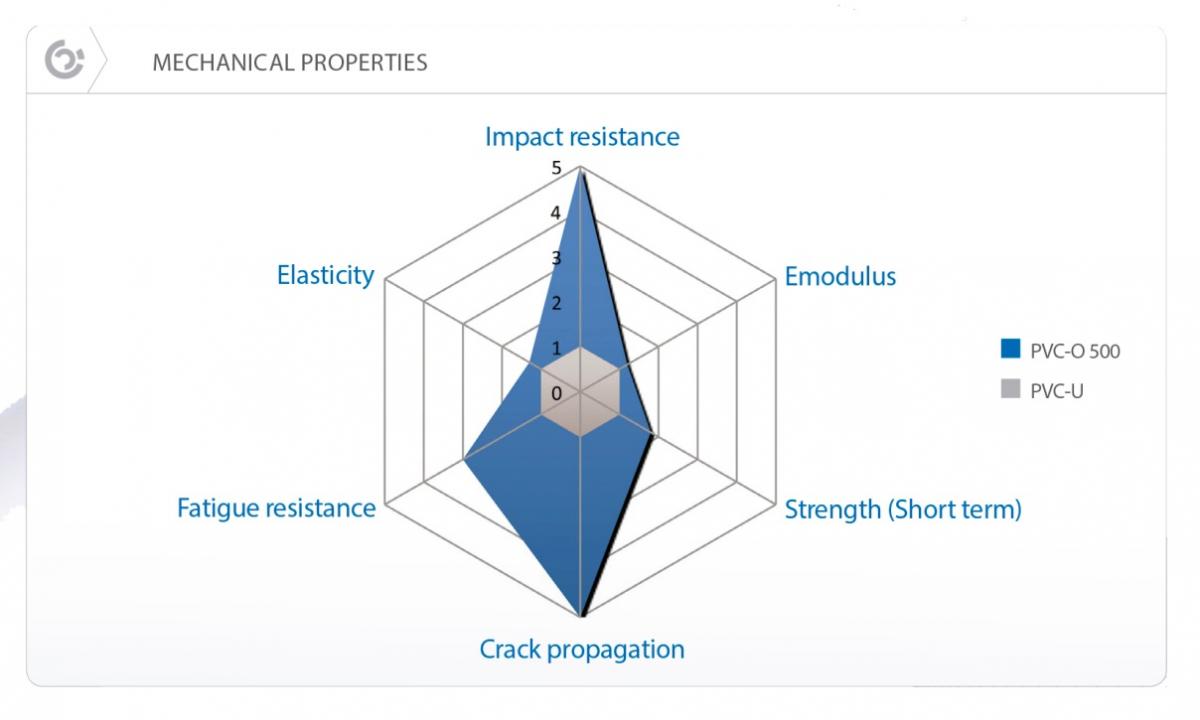

Not only resistance is improved in PVC-O. In the following graph we can see the main mechanical properties affecting to pipes requirements and how they are improved compared with standard PVC.

High short and long term hydrostatic resistance

It is clear how in the short term, PVC-O is a much more resistant material. Analysing the long term behaviour, we can again appreciate a notorious improvement in PVC-O. The slope of the regresion curve is flatter. This means that the material, subjected to a certain stress will be more resistant, so life expectancy is higher.

Corrosion resistance

PVC-O Class 500 is immune to the corrosion caused by natural substances in the soil or agricultural chemicals. Therefore, it is no degradable and does not require any special protection which is translated into cost savings. The quality of the conveyed fluid remains always unaltered.

Regarding the advantages of PVC-O pipes, several can be appreciated compared to pipes of other materials. Among these we can find:

Increased hydraulic capacity

Due to the important reduction in wall thickness, a PVC-O pipe Class 500 can transport for the same nominal diameter much more water than the other traditional materials. In the following image it is possible to appreciate that this difference in water flow capacity is so important that in many cases it will be possible even to reduce the specified diameter for the immediately smaller. This fact contributes of course to reduce the investment in pipelines.

Ductility

Besides this, the ease connection of the pipe and its adaptability to the ground line due to the ductility of the pipe also influences in the higher installation performance of these pipes and, what is more, depending on the line trajectory and pipe, elbows can be removed.

Excellent response to water hammer

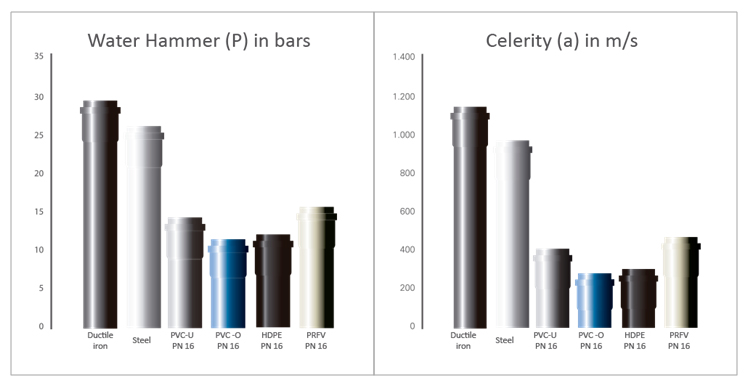

The maintenance cost of this kind of nets is much smaller than in nets of traditional materials. In addition to the extreme resistance to damages during installation that can cause problems in the medium term, it is needed to consider the beneficial behavior of PVC-O Class 500 against the most frequent and worrying effect in a pipe line: water hammer. Due to its elasticity, in the same conditions for a sudden valve closure, a PVC-O Class 500 line, as shown in graphics below, reduces the picks of over pressure acting like a spring, absorbing energy, so the rest of the net is someway “protected”.

Energy efficiency

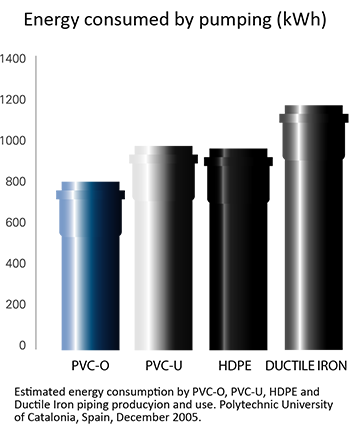

The innovative manufacturing process of PVC-O pipes requires less energy than the needed for manufacturing pipes of other materials thus becoming highly energy-efficient.

Pressure losses are minimized due to the fact that these pipes have an extremely smooth inner wall so, the energy required for transporting water is also lower. The optimization of the energy consumption results in significant energy savings especially, in the pumping stage.

Lower material needs

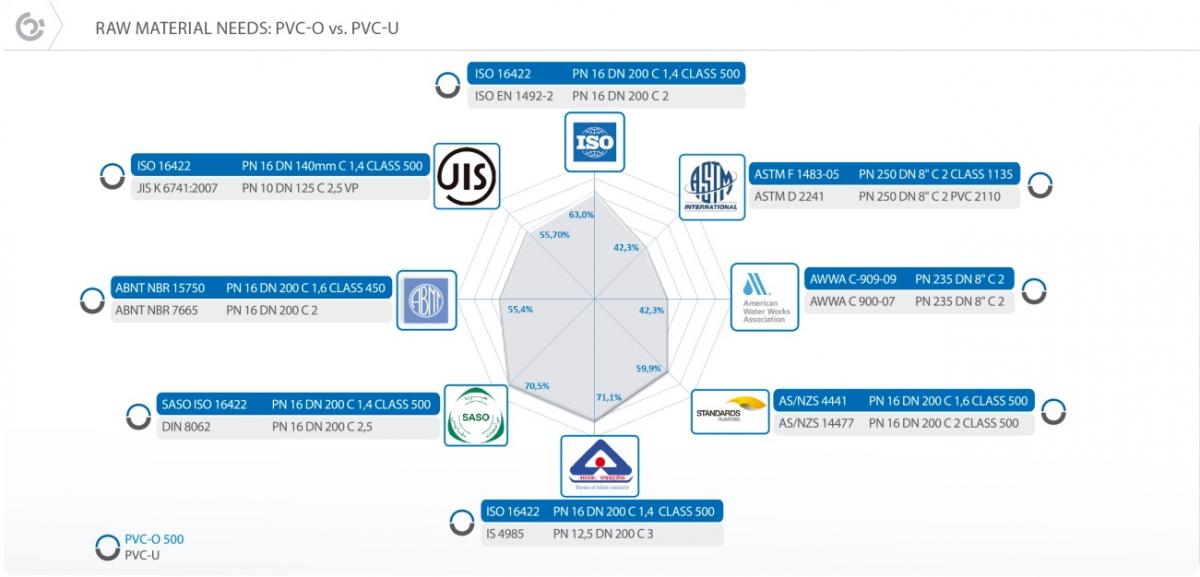

Besides this, maintaining the same performance, PVC-O pipes need less consumption of raw material and this is affecting positively to all the players in the water industry. Less material means less oil consumption, together with a higher flow capacity in the same pipe, and more efficiency for pipe installers.

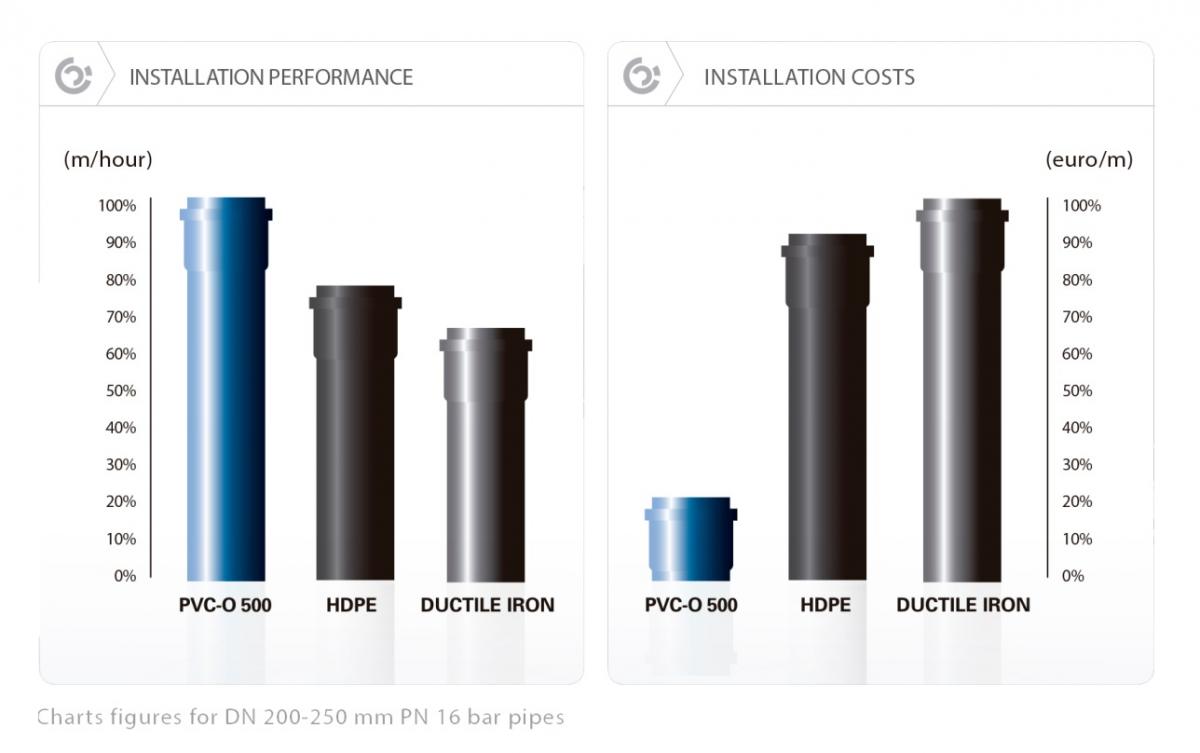

Lower installation costs

One of the main important advantages PVC-O pipe present is the performance in meters / hour installation compared to other solutions. This is due mainly to these facts:

- Lightness and ductility. The speed of installation of these pipes is much higher than with pipes of other materials.

- They are almost indestructible. Their manipulation can be performed with higher discharge and placement performance rates.

- Ease of connecting pipes. This fact provides very high performance rates.

PVC-O pipes are lighter and can be handled easier than pipes made of other materials: they weigh less than the half of PVC and PE pipes, and between six and twelve times less per linear meter than ductile iron pipes of an equivalent nominal outside diameter. This can be better appreciated in the following graph:

The lightness of these pipes allows their handling and installation without mechanical aids such as cranes, feathers, etc., being able to be manually connected pipes up to DN 250mm. In this way, both labor and the use of heavy machinery are reduced, reducing thereby, the installation costs.

Find out more information in our website www.molecor.com