One of the main values on which is based Molecor is its commitment to the environment; due to this most of its efforts in R&D are used to develop increasingly efficient systems to manufacture sustainable PVC-O pipes.

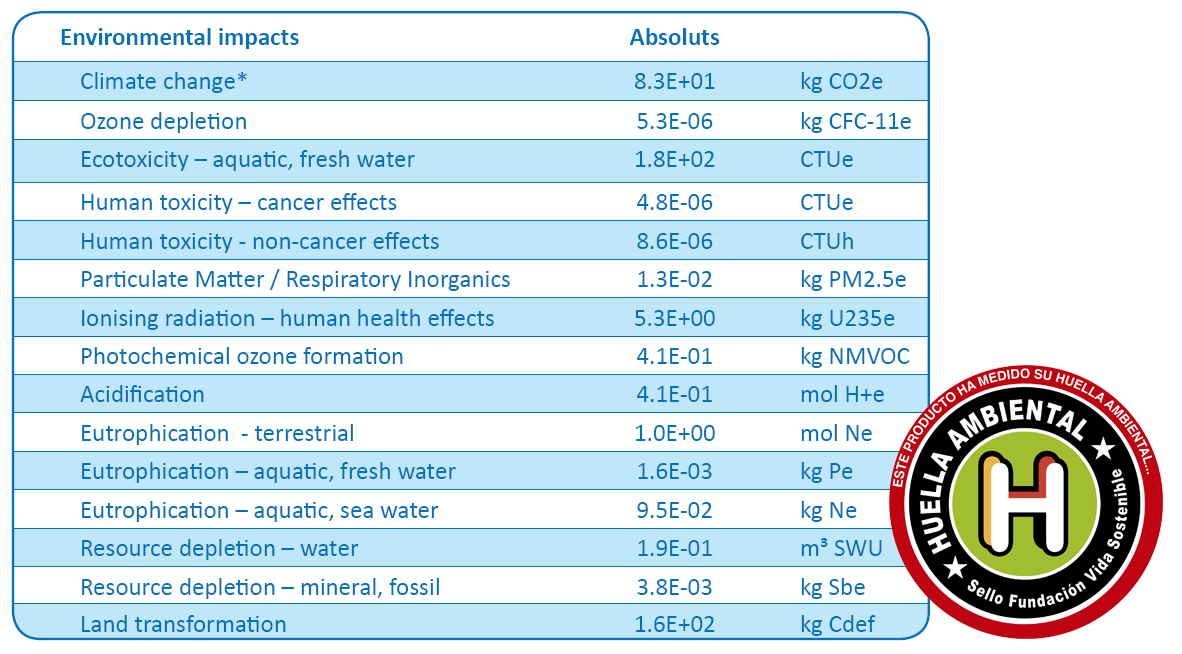

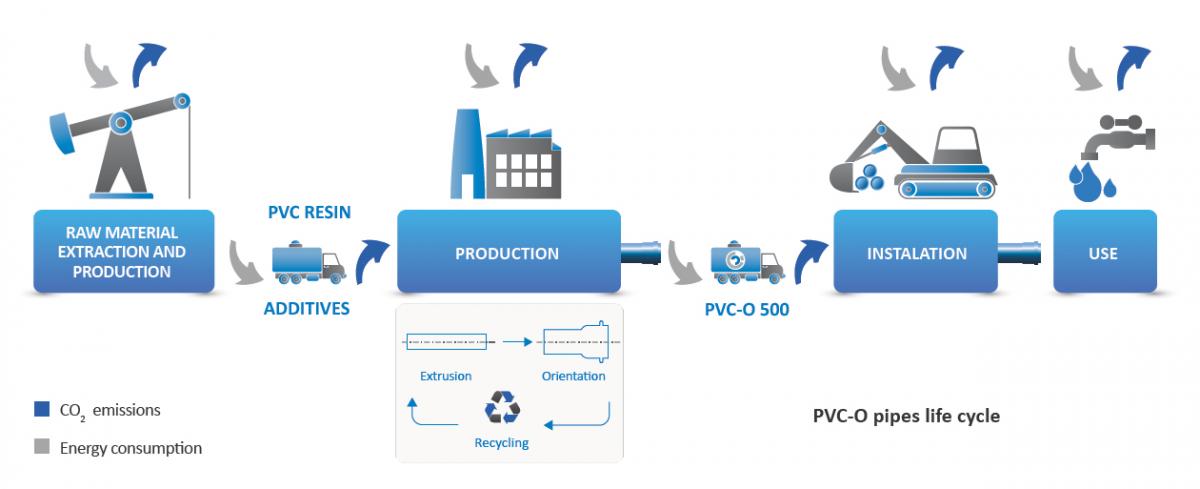

Based on this strong commitment to the environment, Molecor, following the last common methodology of the Recommendation 179/2013 / EC proposed by the European Commission for the Study of Product Environmental Footprint (PEF) has evaluated the environmental impact of the TOM® pipes at all stages of their life cycle from cradle to grave, i.e. from extraction of raw materials to the final disposal of the product, through manufacture, distribution and use of the pipes.

The Carbon Footprint is the best known environmental parameter that has emissions of greenhouse gases into the atmosphere as CO2 expressed into account, and corresponds to the result of the environmental aspect of climate change.

Accordingly, we have studied the effect of the TOM® pipes on 14 environmental impacts that are grouped based on the condition to various means:

• Air and atmosphere: climate change, acidification, depletion of the ozone layer and formation of photochemical ozone.

• Water: resource depletion (water), fresh water ecotoxicity and water eutrophication.

• Soil: resource depletion (minerals), land eutrophication and the use of the ground.

• Human health: respiratory inorganic elements, ionizing radiation, effects on human health (carcinogenics) and effects on the human health (no carcinogenics).

Natural resources efficiency

Only 43% of PVC composition depends on oil. Besides this, thanks to the improvement of the properties obtained during the molecular orientation process, it is necessary less quantity of raw material to manufacture them.

The energy consumption is lower in all the phases of their life cycle: raw material extraction, pipe manufacturing and usage.

Efficiency in resource management

PVC is a 100% recyclable material that can be ground and processed as rework material to be used in the production of other plastic solutions with less technical requirements than these pipes.

PVC-O 500 pipes are 100% recyclable. They can be ground and processed as rework material to be used in pipe production again or in the manufacturing of other plastic products, without losing any of their properties.

Sustainability

TOM® is a sustainable pipe in which design the environment preservation has been taken into account considering aspects as: energy saving, sustainable use of natural resources, constructions durability and respect to environment.

The environmental impact of a piping system depends on its composition and the application thereof, being the kind of material used, the manufacturing process, the high quality of the finished product and its useful life, the main factors that determine the efficiency and sustainability throughout all its life cycle.

Class 500 TOM® PVC-O pipes are the most ecological solution in the market due to their better contribution to correct sustainable development of the planet, as it has been demonstrated by different worldwide studies. These pipes present environmental advantages during their lifecycle.

TOM® pipes are provided with the Huella Ambiental FVS ecolabel, promoted by the “Fundación Vida Sostenible” and the Working and Social Safety Ministry´s company´s responsibility, as grant of their commitment to sustainability.