TR6®: The highest performance at the service of irrigation

Molecor has developed the first PN6 oriented pipe, the new TR6®, intended for irrigation. This pipe has excellent properties and stiffness levels superior to other products available in the market with the same nominal pressure.

Thanks to its excellent physical and mechanical properties, upon analyzing equivalent thicknesses of TR6® and PVC-U PN6 bar pipes, the former have a modulus of elasticity 15% higher compared to the latter, which makes the TR6 pipe exhibit higher levels of stiffness.

TR6® is an Oriented PVC pipe with a PN6 working pressure. With the improvements provided by the molecular orientation, it achieves hydrostatic properties superior to those of PVC-U PN6.

Thanks to the orientation process, TR6® has a much higher impact resistance than traditional PVC-U pipes, up to 2-3 times higher.

Another of the improved characteristics of TR6® compared to PVC-U is its hydraulic resistance. Thanks to the orientation process, this pipe reaches values of 60MPa compared to the 45MPa of PVC-U. In addition, the fatigue behavior of TR6® is also higher.

All TR6® pipes are manufactured following a strict quality control process that allows the detection of any imperfection that may occur in the extrusion process, guaranteeing the quality of the manufactured pipe at all times.

TR6® PVC-O pipes are the most sustainable solution on the market for irrigation applications, due to their lower carbon footprint as well as lower energy consumption throughout their useful life.

The better elastic behavior of TR6® compared to PVC-U allows it to withstand large deformations of the inner diameter while immediately recovering its original shape.

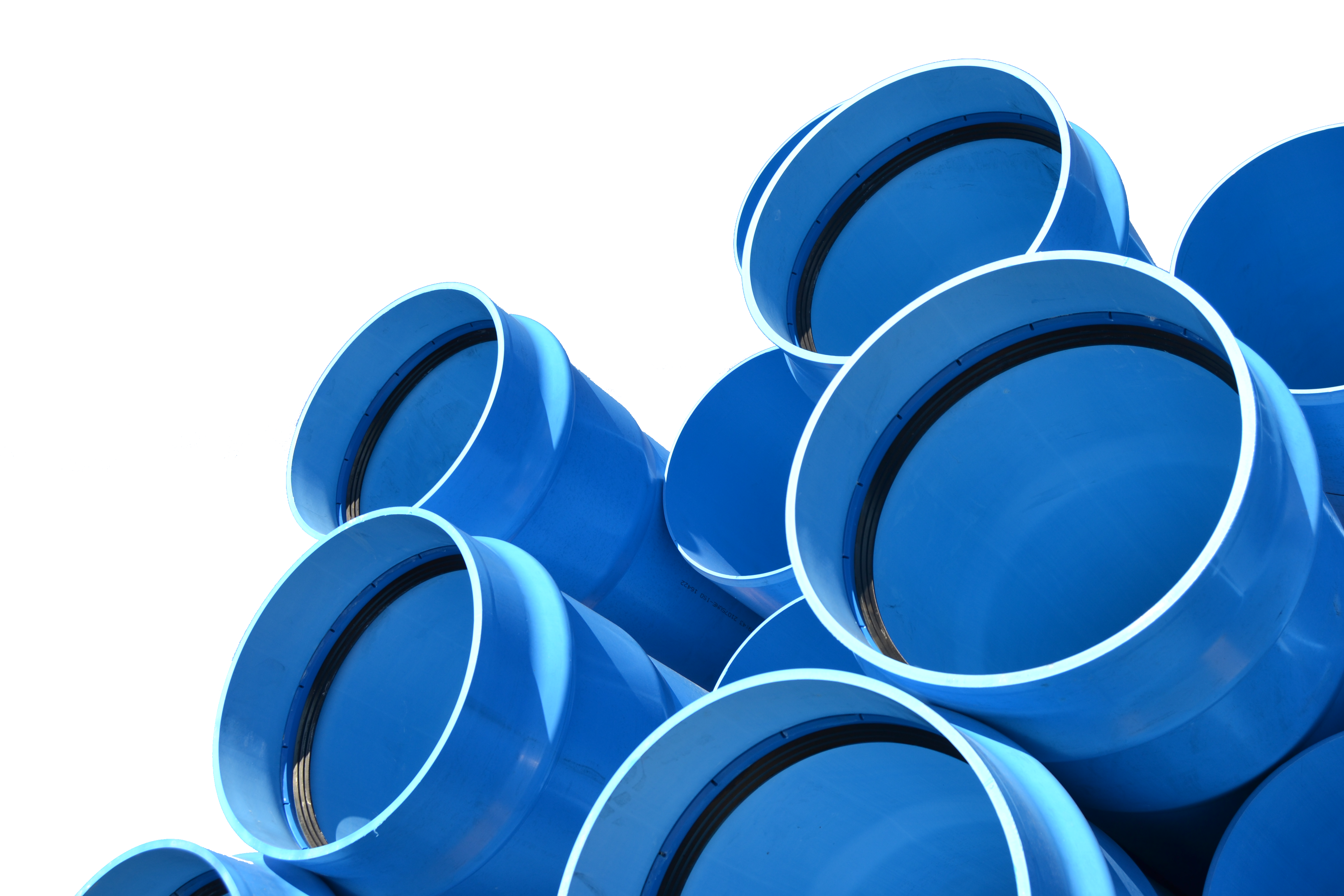

The sealing gasket is composed of a PP ring and a synthetic rubber lip which makes it an integral part of the pipe, preventing it from rolling during assembly and displacement from its location, thus achieving a complete seal.

The TR6® pipe is manufactured with the technology developed by Molecor, which allows full traceability of the process guaranteed thanks to the M.E.S. (Manufacturing Execution System) process monitoring system with 4.0 connectivity.

Easy connection

Socket system for easy installation

More than 100 years of useful life

TR6® pipe maintains all its characteristics for over 100 years

Water hammer resistance

Supports network openings and closings exceptionally

High impact resistance

No crack propagation

Great ductility

Supports large deformations of the inner diameter

Watertight

The socket is manufactured in the same process as the rest of the tube

Immune to corrosion

No need for special protection or coating

The highest installation rate in m/h

Thanks to its lightness, flexibility, ease of connection and resistance

Great lightness

TR6® pipe is lighter and more manageable than other products available on the market

- Cost efficiency. Manual handling up to DN350 mm

- Natural resources Usage optimization. Optimization of the use of natural resources and 100% recyclable

- Energy efficiency. Lower energy consumption throughout the life cycle

- Greater elasticity. Elasticity greater than 15% compared to other solutions on the market

- TR6 pipe diameters: from DN90 mm to DN400 mm

- TR6 pipe pressures: PN6 bar

- Higher rigidity levels than other products

The pipes are supplied in total length (including the socket length) of 6 meters. Other lengths will be studied for special projects.