ecoFITTOM®: the solution for the uniformity in the water networks

Molecor, in its continuous process of Research and Development has developed and exclusive and highly efficient industrial system for the manufacture of PVC-O fittings, with which the company has been capable of manufacturing a product with better mechanical properties.

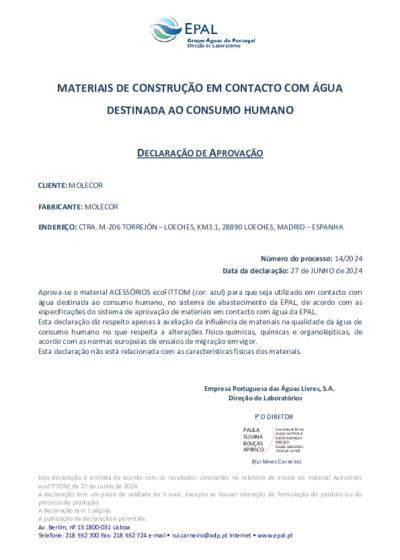

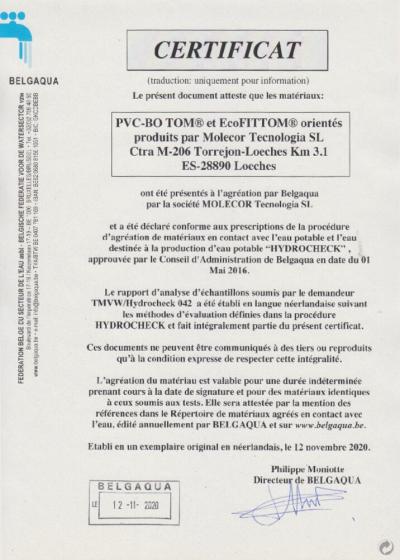

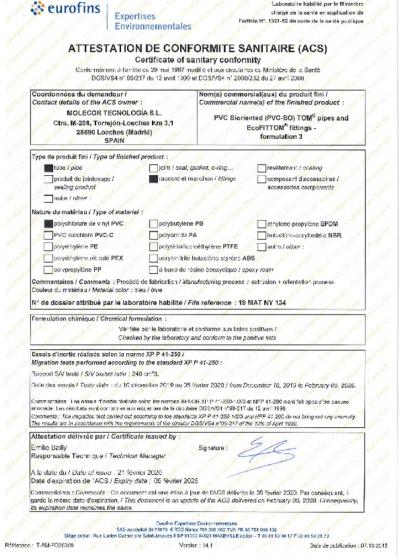

ecoFITTOM®, the first fittings in the world in PVC-O, present excellent improvements in the mechanical properties of PVC. These improvements allow to manufacture ecoFITTOM® consuming less raw material and less energy obtaining a product with higher hydrostatic resistance and higher resistance to impact than fittings of other materials. Besides this, ecoFITTOM® presents an excellent behavior against water hammer, complete watertight, maximum chemical resistance and ductility.

With ecoFITTOM® Molecor offers a continuous system in PVC-O; this material continuity guarantees the same hydraulic and mechanical properties in the different elements of the network, in the pipes as well as in the fittings.

This fact, guarantees, at the same time, total water quality and, as it has just been said, an important reduction of the water hammer effect.

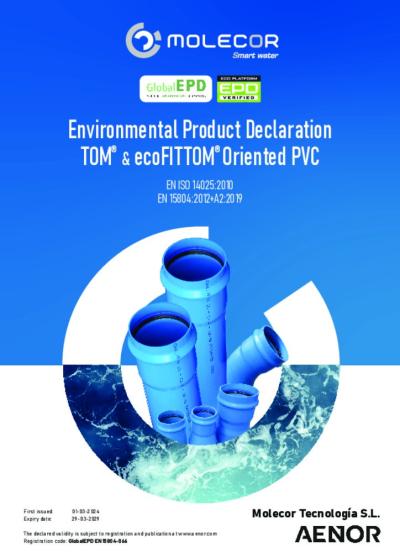

Molecor’s commitment to environment can also be seen in the ecoFITTOM® manufacturing process. This is a 100% recyclable product for which manufacture it is necessary a lower quantity of raw material but offering, at the same time, the best properties for the conveyance of water under pressure.

These fittings can be used in networks for the transportation of drinking water, irrigation systems, industrial applications, sewage, infrastructure networks, fire protection nets, etc. among other applications.

For more information about the PVC-O fittings ecoFITTOM® you can download the technical sheet:

This project has received recognition from the European Union for innovation in the use of innovative materials and technologies for manufacturing and processing:

"EXCELLENCE, IMPACT, QUALITY AND EFFICIENCY IN IMPLEMENTATION"

Hydrostatic resistance

Guarantee of quality and useful life of more than 100 years

Maximum resistance to water hammer

Low speed and low probability of breaking when opening and closing networks

High impact resistance

Decreased risk of rapid cracks

Maximum ductility

They withstand large circumferential stresses

Guaranteed tightness

High quality gasket

Chemical resistance

100% corrosion resistance

- Greater uniformity in the networks. Same properties as in TOM pipes

- Cost efficiency. Light and manageable

- Environmental advantages. The lowest CO2 emissions during their life cycle

- Installation advantages. Light, ductile, easy to install

- PVC-O fittings diameters: from DN110 mm to DN400 mm

- PVC-O fittings pressure: PN16 bar

- Wide variety of figures. In the process of expanding the range