Although other applications are not ruled out, TOM® pipe is especially suitable for underground installations.

In this article, we would like to provide the information and necessary points to study for dimensioning the trenches correctly:

Excavation:

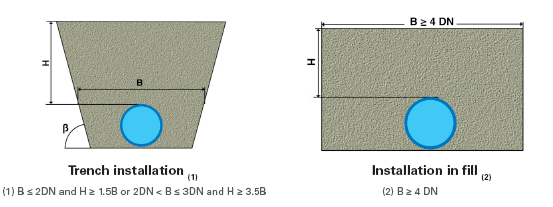

For calculation purposes and for this article, we are going to consider the most common installation case: Installation in trench or in fill. The required data are:

- Covering height above the upper generatrix of the pipe, H, in meters.

- Width of the trench at the level of the upper generatrix of the pipe, B, in metres. In case of installation under embankment, it is considered that B ≥ 4 DN.

Inclination angle of the walls of the trench, β, in degrees.

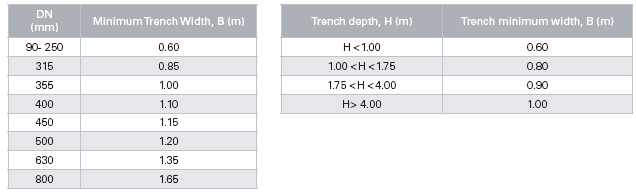

As a general rule, when there is no traffic, the upper generatrix of the pipe will be at a minimum depth of 0.6 metres, extended in the case of road traffic to a minimum depth of 1 metre, once verified by the corresponding calculation, according to the worst-case scenario for use. The minimum trench widths shall be based on its nominal diameter and depth:

Bedding specifications and overhang ratio:

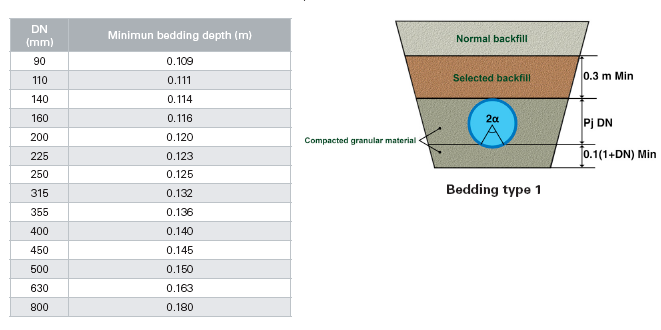

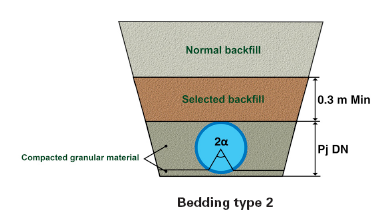

The bottom of the trench must ensure homogeneous bedding that is even and firm all along the pipe. The required data are the bedding angle 2α, in degrees, and the overhang ratio, Pj. For calculation purposes, two types can be considered:

TYPE 1: This bedding type consists in a continuous layer of granular material compacted on top of which the pipe lies. Bedding must be evenly compacted along its length and it must cover the pipe according to the bedding angle 2α. The overhang ratio for this type of support is Pj = 1.

In short, for optimum installation performance, a bed of sand (or other fine granular material) must be laid with a thickness of between 10 and 18 cm above the supporting pipe. The pipe cannot be laid directly on rocks or large stones under any circumstances.

TYPE 2: In this bedding type, the pipe lies directly on top of the bottom of the trench, or natural ground, in case of a fill-type installation.

It must be used only in sandy soils free of clods and stones. Once the pipe has been installed, a selected backfill must be added and compacted on both sides of the pipe to ensure the bedding angle 2α. The projection ratio for this bedding type is Pj = 1.

Once the pipes have been laid in the centre line of the trench and the couplings have been made, the backfill must be made on both sides of the pipe. The backfill must be made by tamped layers of a thickness not exceeding 15 cm, constantly keeping the same height on both sides of the pipe, up to its socket, which must be visible. The degree of compaction must be above 95% Standard Proctor. The degree of compaction to be obtained is the same as that of the bed. Special care must be taken to ensure that no gaps are left unfilled underneath the pipe.

The trench must be backfilled to a height of thirty centimetres above the socket of the pipe, with selected backfill. It must be tamped with a light piston on both sides of the pipe and left uncompacted in the centre across the width of the horizontal overhang of the pipe. Then the backfill can be made using land from the excavation, compacted in successive layers of a height of no more than 20 cm and a degree of compaction 100% Standard Proctor.