Pressure pipes can have different types of damages and defects, due different causes occurred in all product value chain; from industrial pipe production until the installation and end of their working life. Since microstructural defects as tiny holes due air and bad gelation in the manufacturing process, passing by the incorrect packaging and wrong secure cargo in transportation, installation and manipulation bad practices, to their usage with non-projected hydrostatic pressures due non satisfactory net design or usage. In this article we are going to focus interest on the damages caused by impacts, commonly happened in the product transport manipulation and in the installation works, which may imply a pipe collapse.

It is being known from more and more hydraulic management specialists and sector people that PVC-O pipes are the new generation of PVC, a product which maintains the advantages and eliminates the weakness of the traditional PVC-U, considered the most efficient solution for water transportation nowadays. Mechanically speaking, one of the feebleness of pipe materials is the impact resistance. Imagine a weight falling as a rock falling and impacting to a pipe which is laying in a trench, or a bad cargo manipulation when unloading; depending of the falling height and the material, it may cause a break, a scratch to the pipe protection that will permit oxidation, or a structural small dislocation that will grow and consequently bring high possibilities of failure in the future.

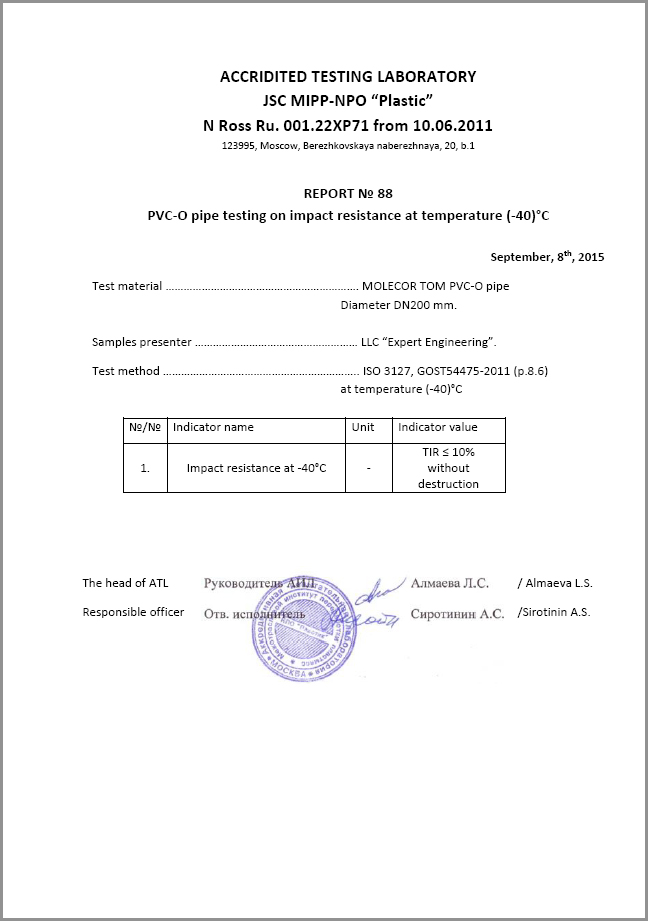

Breakages in PVC-O due falling weights are almost impossible to see, because due the nature of the material its impact resistance is one of its best mechanical properties. As per its ductile behavior, elasticity and demonstrated impact absorption, reflected first in its higher standard test requirements and later in its proven successful installations in the field, having a PVC-O pipe is a guarantee of durability in this situations. Even in low temperature situations, when other materials use to show higher brittleness, PVC-O pipes accomplish impact requirements.

Even there is not a visible break or deep crack and it is just in the surface, when pipe suffers an impact, future loads applied to the pipe will cause a propagation of the crack unavoidably ending in a pipe collapse. PVC-O pipes, due their laminar structure, do not permit the propagation of the cracks because the dislocation cannot jump between lays easily as in other materials. This is one of the most common causes of impact failures, remarkable solved by PVC-O pipe material.

Scratches in surface are always not desired, but unfortunately they are inevitably in works and transport. PVC-O is a non-degradable product, with a layered structure consistent enough for not needing of corrosion-resistant coating. PVC-O astonishing chemical resistance, quality maintained equal to PVC-U as per its equal chemical composition, is able to bear all kinds of erosive soils, and not affected by corrosion if scratch is produced.

In resume, PVC-O pipes are able to withstand impacts and their derived complications that may arise, without compromise their life expectancy, and definitely being a safe bet for all water resources managers.