The global plastics converting industry faces a hitherto unknown shortage of raw materials. This situation endangers the economic survival of many SMEs as well as the production of different products and ultimately, end customers can also suffer damage due to interruptions or delays in the delivery of products.

In the case of Molecor, this problem is not as acute as it can happen in other processing industries since, thanks to its optimized technology for the manufacture of Oriented PVC pipes and fittings, the need for raw material to obtain the final product is much less than in the case of the manufacture of other similar products. Thus complying with SDG 12, related to responsible production and consumption, an objective that the company also complies with an Integrated Management System based on the UNE-EN ISO 9001: 2015 and UNE-EN ISO 14001: 2015 standards, based on continuous improvement.

The exceptional mechanical properties of TOM® pipes and ecoFITTOM® fittings, obtained through the molecular orientation process, allow this very important saving in raw materials, of up to more than 50%. For the same nominal outside diameter, TOM® and ecoFITTOM® require less PVC.

The exceptional mechanical properties of TOM® pipes and ecoFITTOM® fittings, obtained through the molecular orientation process, allow this very important saving in raw materials, of up to more than 50%. For the same nominal outside diameter, TOM® and ecoFITTOM® require less PVC.

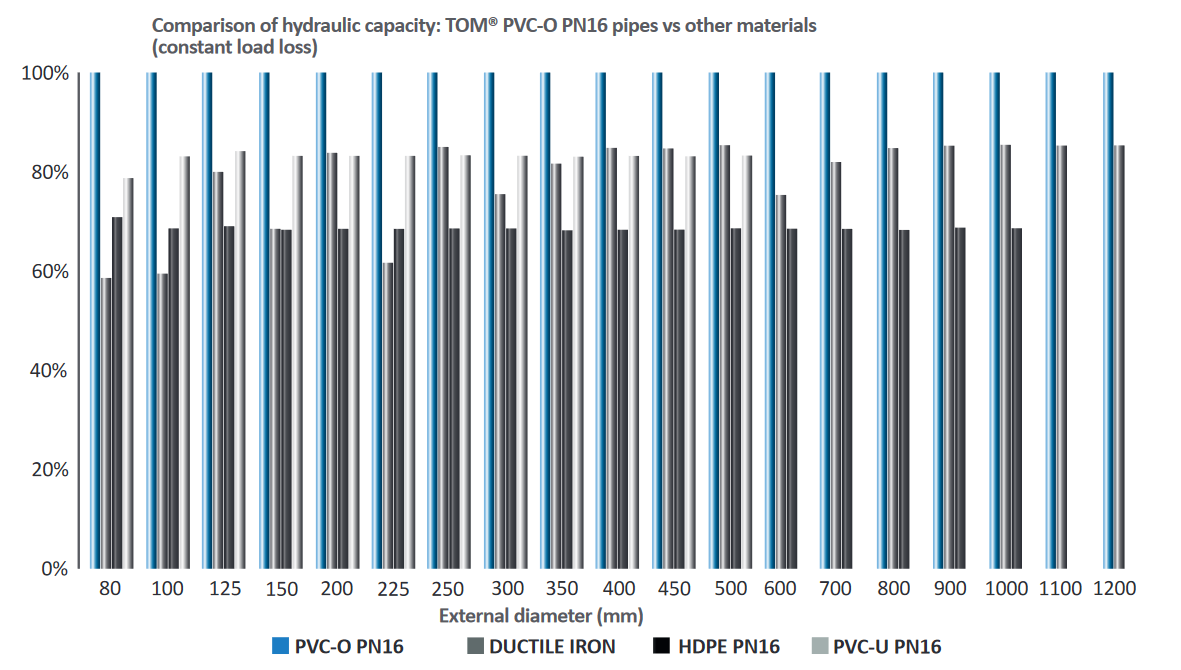

As a result of this reduced need for raw materials, TOM® Class 500 pipes and ecoFITTOM® PVC-O fittings offer 15% to 40% more hydraulic capacity than pipes made of other materials with comparable external diameters (PVC -U, PE, ductile iron), which will always give the best efficiency between the investment cost and the available hydraulic capacity, making them, therefore, more competitive products and, at the same time, more efficient and sustainable. Thanks to their complete sealing and long service life, they are also the best ally in saving water resources. In addition, they comply with SDG No. 6 related to clean water and sanitation, since these pipes and fittings are products with a long useful life that guarantee total water quality.

Reducing the consumption of raw materials is a common objective at the international level in the field of sustainable development and it is an objective that Molecor has fulfilled since it was founded.

The energy used in the manufacturing process of the TOM® pipes and ecoFITTOM® fittings is applied through a specific air distribution that allows the optimization of resources since it uses the least possible amount of energy obtaining the maximum performance, turning them into products very sustainable. Thanks to this highly energy-efficient production process and the responsible consumption and use that Molecor makes of it, ODS 7 is another of the objectives that Molecor develops.

In addition to this, PVC-O pipes and fittings are 100% recyclable. They can be ground and reprocessed as recycled material for use in the manufacture of any other type of plastic product.

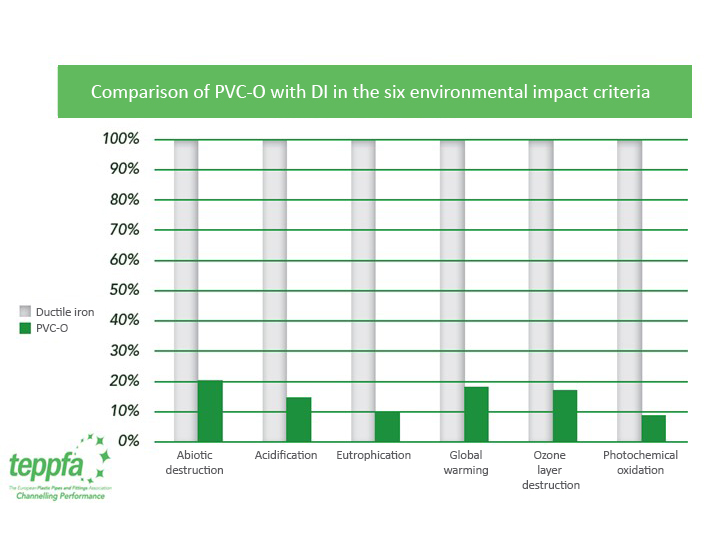

These products have become the most ecological solution of all that exist in the market, due to their best contribution to the correct sustainable development of the planet, as shown by different studies worldwide, among which we can highlight: Estimation of energy consumption and of the CO2 emission associated with the production, use and final disposal of PVC, PEHD, PP, Foundry and Concrete pipes (Universidad Politécnica Catalunya) and the study PVC-O Environmental Product Declaration TEPPFA (The European Plastics Pipes and Fittings Association), and present environmental advantages in all phases of their life cycle, extraction of raw materials, manufacturing and their use, thus being the most efficient from the energy point of view. Also contributing in this way that TOM® pipes and ecoFITTOM® fittings allow the construction of sustainable environments (SDG 11).

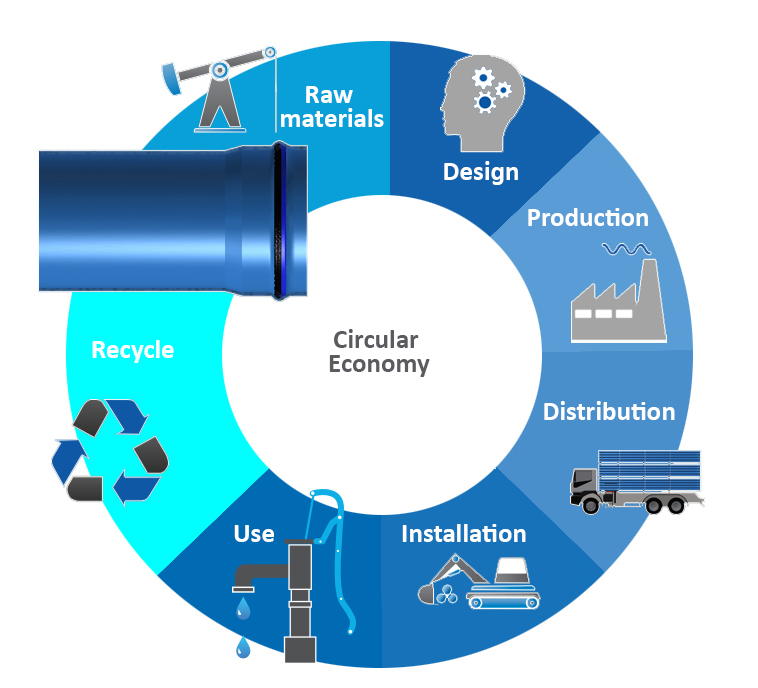

This sustainability is evident in the current situation in which the crisis of resources; the problem of climate change and the need for economic growth have given rise to a new strategy, the Circular Economy, which aims to reduce both the consumption of new materials and the production of waste, closing the circle of economic and ecological flow of the resources.

This concept of circular economy is directly related to the minimization of consumption of raw materials and energy, and therefore, with the reduction of emissions into the atmosphere, thus the effect on climate change and the anthropogenic impact on the environment can be mitigated, always taking into account the impact of products throughout their life cycle.

In this way, among the different environmental advantages that Oriented PVC presents in all phases of its life cycle is greater efficiency in terms of the use of natural resources. In short, we can affirm that Molecor applies ecodesign to manufacture Oriented PVC (PVC-O) pipes and fittings with a very high useful life, reducing the consumption of natural resources, both raw materials and energy during their manufacture, thanks to the development of an exclusive, highly energy-efficient technology and, therefore, making its Oriented PVC pipes and fittings the most competitive products for the transport of pressurized water.