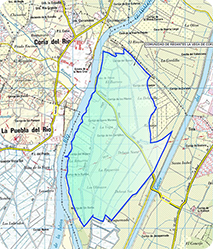

The Irrigation Community La Vega de Coria has an irrigated area of 1,367.21 ha, mostly gravity-fed, dedicated to numerous crops, mainly cotton, maize, potatoes and oranges, located on the left bank of the Guadalquivir River, in the municipality of Coria del Río. The irrigation installations date back to 1986.

The municipality of Coria del Río is located in the south-western sector of the province of Seville. Its territory lies within the districts of Aljarafe and La Vega. The municipality is also close to the Marismas del Guadalquivir region. This community has a concession for the use of public water from the River Guadalquivir of 957.05 l/s and authorisation for the abstraction of a maximum annual volume of 9.57 Hm3/year.

Coria del Río has an average temperature of 17.5 °C, an average minimum of 11.5 °C and an average maximum of 24.3 °C, with an average annual rainfall of 1.4 mm/day, corresponding to 539.8 mm. In a normal hydrological year, rainfall is concentrated between October and May, with a dry period for the rest of the year. Precipitation is very irregular depending on the hydrological year, being clearly identified with the Mediterranean climate: very wet periods with abundant rainfall, and other dry periods.

Agriculture covers 68 % of the municipality’s surface area, mainly dedicated to the cultivation of herbaceous species (3,529 ha) and to a lesser extent to woody plantations (727 ha). Cotton is the largest irrigated crop, with 742 ha; the main rainfed crop is wheat, with 75 ha. Among the woody plantations, the most important is the cultivation of orange trees, with 354 ha, irrigated, and the cultivation of olive trees as table olives, with 102 ha, rainfed.

The Project for the improvement and modernisation of the Irrigation Community La Vega de Coria. M.D. Coria del Río (Seville) aims to modernise the facilities, for which the following points for improvement have been established:

- Improve efficiency in the use of water by reducing losses in the system.

- Optimise investment and operating costs, generating greater profitability for the farmer.

- To ensure the availability of water for irrigation on all fields.

- To have a regulation system for the pressurised irrigation area.

- Reducing energy dependence on the NETWORK, through the implementation of a system of self-production of electrical energy. Improvement of water quality and reduction of suspended solids in irrigation water.

- Installation of instrumentation for the active control of the automatic detection of water losses.

Designer, project management and construction company of the works.

This project was drawn up at the request of the Irrigation Community of La Vega de Coria, by WATS Técnicas de Ingeniería S.L., a company specialising in hydraulic engineering, energy, agronomy and the environment. WATS Técnicas de Ingeniería S.L. was also in charge of carrying out the works management and technical assistance for the execution of the project. The work was assigned after a public tender process to Talleres y Grúas Gonzáles S.L., a company specialised in the design and execution of all types of hydraulic works at national level.

The Irrigation Community of La Vega de Coria had the following elements:

- The main collection and elevation group from the Guadalquivir river, consisting of four immersible pumping units. The pumping pipes discharge into a chamber, from where the water is distributed to the main network of irrigation ditches.

- Main transport network using irrigation ditches: The layout of these irrigation ditches is raised above the ground. They are made of concrete and have a semicircular geometry.

- Plot distribution network: Made up of semi-circular ditches and, in some cases, pressurised pipes buried in concrete.

- Pumping station: responsible for raising the flow of water circulating through a section of the main transport network to another, downstream, at a higher elevation.

- Network of drainage channels, into which the collectors at the end of the irrigation plots drain.

The existing network of irrigation ditches in the community was in a poor state of conservation in a large part of its layout, which greatly limits its transport capacity and causes losses of water resources, clearly harming the community and the efficiency of water use management.

The main pumping group from the River Guadalquivir consists of four semi-axial immersion type pumping units, of which up to three operate simultaneously, the fourth being a reserve unit for lifting large flows at moderate hydraulic pressure levels.

The discharge pipes at the outlet of the pumps have a nominal diameter of 700 mm in steel. They discharge into a water box, which gives rise to the main network of irrigation ditches, with an internal height of 4.50 m; the upper level of the chamber is 7.75 m.

Irrigation water was distributed mainly by gravity through a network of concrete ditches with a semi-circular geometry, which are raised above ground at a sufficient height to guarantee the distribution of the water.

The main network of irrigation ditches has a total length of approximately 13 414 metres. It has a first section of 470 m, with a double layout of ditches, with a section of 1.50 m wide at the crown and an internal height of 1 m each;

The network of main distribution ditches runs parallel to the community roads; they are crossed by means of siphons. On each side of the road, there are water boxes, connected to and flush with the canals at the crest, at the bottom of which there is a concrete pipe, below the level of the road, which overcomes the obstacle.

The main transport network ends in a type of irrigation channel with a smaller cross-section and transport capacity than the first ones. It also has a semicircular geometry, with a section of 1.10 to 1.15 m wide at the crown and 55 cm high inside. These ditches are arranged at hydraulic gradient levels of between 6.50 m and 5.30 m, depending on the one in question.

The water distribution network within the irrigation community plots is carried out by means of irrigation ditches and, in some cases, by means of pressurised pipes buried in concrete. At present, a high percentage of the community’s transport infrastructures continue to be free-flowing by means of irrigation ditches.

The transport ditches in plots also have a semicircular geometry, with a variable section of 70-75 cm wide at the crest and 40-55 cm high inside, depending on the ditch in question.

Each ditch supplies a variable extension of land, and a different number of hydrants, of different types: one, two or three outlets. In turn, the hydrants can be arranged in chambers or on the surface.

The Irrigation Community of La Vega de Coria has a pumping station that raises the flow of water circulating through a section of the main transport network to another, downstream, at a higher level.

The Irrigation Community of La Vega de Coria has a network of drainage channels into which the collectors at the end of the irrigation plots drain. These are of variable diameter, between 200 and 250 mm, made of steel; they have butterfly valves for opening and closing the collector. These drain the excess irrigation water into the drainage network to avoid the possible silting up of suspended solids inside the irrigation pipes after irrigation has finished.

The project proposed the following measures and solutions to improve the hydraulic operation of the water distribution facilities:

- Pressurisation of the water distribution ditches by using plastic pipes, which will have the following benefits:

- Reduction of leaks and consequent increase in the efficiency of water use.

- Increased transport capacity (lower value of the friction coefficient).

- Elimination of losses due to evaporation of the water surface in the irrigation ditches.

- Optimisation of the hydraulic pressure head.

- Raising and improvement of the ditch of the main transport network, when it is necessary to increase the hydraulic pressure height for the optimal supply to the hydrants in the secondary transport network.

- Reinforcement of the structural support elements of the ditches: pilasters and braces.

- Waterproofing of the main transport ditches.

- Remote control. instrumentation for measuring safety spillways. Active control devices for automatic leak detection.

- Installation of two photovoltaic fields to supply energy to the existing pumping stations.

The actions carried out are as follows:

- Pressurisation of the irrigation ditches

- Pipes

- Suction cups

- Manholes

- Hydrants

- Drains

- Filtration elements

- Reinforcement of structural support elements

- Waterproofing of the main transport ditches

- Remote control. Measurement instrumentation of safety spillways.

- Self-production of energy. Photovoltaic fields in catchment and re-pumping stations.

Pressurisation of irrigation ditches

The project considered the modernisation of the transport facilities to the plot, by replacing the current irrigation ditches and underground concrete pipes with pressurised plastic pipes.

The use of metal pipes was ruled out for the following reasons:

- In plastic pipes, a lower head loss is obtained due to the low roughness they present.

- The plastic pipes are highly resistant to corrosion, abrasion and the effect of chemical agents, which prevents the generation of oxides. This factor is important, as the Irrigation Community is under the influence of the lower section of the Guadalquivir river.

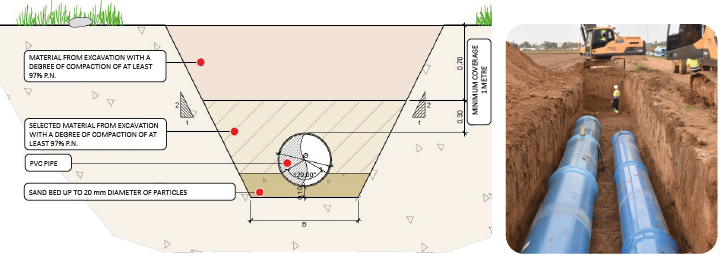

These pipes were laid in trenches, in optimal conditions for the minimum support of traffic loads of tractors and farming materials, with a total weight of less than 12 tonnes, when the pipelines run inside the plots.

The standard trench has a minimum width of 0.5 m in addition to the nominal diameter of the pipe, when this is less than or equal to 315 mm, 0.7 m in addition to the nominal diameter of the pipe, when this is greater than or equal to 400 mm, and 0.85 m in addition to the nominal diameter of the pipe, when this is greater than or equal to 800 mm. The pipe is installed on a bed of sand of minimum 10 cm thickness, up to 20 mm particle diameter, with a minimum compaction degree of 95 % N.P., and a support angle of 120o. The backfill material for the trench came from the excavation itself, with a minimum compaction degree of 97 % N.P., and a backfill height above the upper keystone of the pipe of 1m.

The excavation slopes of the trench shall be: 1(H):2 (V).

All pipelines are fitted with tri-functional low pressure suction cups at high points where air pockets accumulate, 3” (80 mm) for 315 mm or 400 mm pipes, 4” (100 mm) for 500 mm or 630 mm pipes and 6” (150 mm) for pipes of 800 mm diameter or larger. These elements are installed together with shut-off valves (gate valves) to shut off the flow through the suction cup for maintenance operations.

When the section of pipe has a considerable route, “manholes” are provided in prefabricated concrete manholes with a nominal diameter of 1000 and 1500 mm, for access to the cleaning material line, for operation and maintenance work.

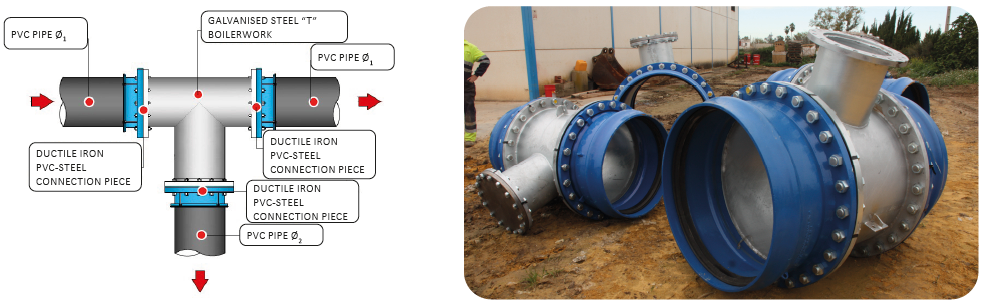

The layout of the pipelines and their development require a change in the alignment of the network, or even branches, and a variation in the diameter of the pipe, which are carried out by means of special cast iron and boilermaking pieces. The reducers, when necessary, are always made after the derivation, so as not to increase the resistance to the passage of water, before the bifurcation of the network.

In the pressurisations of ditches R55 south-west, R55 south-east and action 24, shut-off valves will be designed to allow the most suitable configuration of the distribution network to be selected, depending on the needs of the plots to be supplied.

For this purpose, gate valves will be provided, with resilient-seated lenses, body, cover and gate made of ductile cast iron GGG-50, cold-pressed AISI 420 stainless steel shaft, epoxy paint coating.

Water is supplied to the plot by means of surface hydrants, with one, two or up to three feed hydrants, each with a nominal diameter of 200 or 250 mm, made of galvanised steel. Each hydrant is fitted with a corresponding butterfly-type shut-off valve of the same size as the diameter of the outlet. Each hydrant, at its highest point, has a 3” or 80 mm diameter suction cup. This suction cup is placed behind a shut-off valve, which prevents the expulsion or uncontrolled entry of air into the interior of the pipes in the event of dismantling the suction cup due to maintenance or repair operations.

In pressurised pipes, drainage points are planned for the evacuation of irrigation surpluses in the final section or in the low points of the profile. These drains are fitted with Wafer type butterfly valves with a nominal diameter of 250 mm in ductile cast iron, operated by means of a reducing handwheel, which regulate the operation of the drain when necessary.

The above drains evacuate excess irrigation water to the community drainage network. At the drainage points without direct discharge to the drainage network, two wells are provided by means of prefabricated concrete rings, one for the valve and another that acts as a back-up for connection to a drainage pump. For the other networks, a single manhole is to be provided with prefabricated reinforced concrete rings. The manholes are laid on a 0.20 m thick reinforced concrete foundation slab.

To prevent the passage and circulation of elements (leaves, etc.) inside the pipes, filtration elements are planned to be installed in the ditches, at the entrance to the siphon chambers, from where the pressurised pipes start. These elements are designed in AISI-304 stainless steel, with rectangular geometry, built with 2 mm thick bars, 15 mm apart.

Reinforcement of structural support elements

This project involves the reinforcement, reconstruction and repair of disintegrated and disaggregated areas of the structural support elements (pilasters and braces) and of the water transport ditches. This reinforcement is carried out by means of a single-component repair mortar coating based on cement, synthetic resins, silica fume and reinforced with fibres. The reconstruction of the pillars is carried out using this material, in a variable thickness, depending on the magnitude of the wear and tear in each case.

In order to carry out this action, the surface to be reinforced will first need to be cleaned and conditioned, by means of manual chipping and cleaning, brushing and scraping. Subsequently, a layer of resin will be applied to act as a bonding bridge between the existing structure and the new mortar applied, of the epoxy-cement type for reinforcing steel.

Waterproofing of the main transport ditches

One of the most important actions considered in this project is the waterproofing of the transport facilities at those points or joints which, due to their deterioration or useful life, generate filtrations and water losses in the network.

To carry out this work, a highly elastic joint sealing system is considered, consisting of a 25 cm wide polyolefin-based strip and epoxy resin. This work requires prior sanitising and cleaning of all joints, and drying of the joints.

The joints to be waterproofed are those that appear between consecutive sections of the canal, every 5 m, of a length equal to the perimeter of each type of ditch: R88, R76 and R55.

Similarly, the longitudinal joints that appear between the structure of the ditches and the screed provided by the community in some sections will be waterproofed using this system.

Remote control. Measurement instrumentation for safety spillways

At the end of the main sections of irrigation ditches, the community’s main transport network has safety elements for the discharge of excess water into the internal network of drainage collectors: spillways.

This project considers the use of measuring instrumentation, level sensors, upstream of the spillways or on them, to control the levels of water discharged by these structures. These elements generate warning alarms in the event of uncontrolled discharges into the drainage network, which facilitates the operation and management of the hydraulic functioning of the community (stopping pumps).

New spillway chambers are also planned, annexed to the siphon chambers, at those points in the network where uncontrolled spillage of water can be foreseen at the crown of the latter, as a consequence of the unexpected closure of the hydrants or intakes, and the continued operation of the motor-pump unit and derivation of the flow to that area.

Self-production of energy. Photovoltaic fields at pumping stations and re-pumping stations

Two photovoltaic fields are planned to reduce energy dependence on the grid in the energy supply of the catchment pumping station and the re-pumping station in the irrigation network. These new installations are named as follows:

- Solar field 1: for the supply of energy to the catchment pumping station.

- Solar field 2: for the energy supply to the re-pumping station.

Irrigation networks require a profound upgrade to respond to the demands of the agricultural sector and responsible water management. The modernisation of irrigation networks not only represents an opportunity to optimise water use, but also to drive the transformation of the agricultural sector towards a more sustainable, productive and resilient model in the face of the challenges of climate change, the improvement and modernisation project of La Vega de Coria irrigation community is an example of this.

Pipes are essential components in the design of irrigation networks, and the right choice is crucial to ensure the efficient and long-lasting operation of the system. When choosing the material for the pipes, several factors must be considered that go beyond the simple proven quality. Among the most important parameters to take into account are: the hydraulic capacity, the behaviour of the material with regard to the continuous transients that occur in an irrigation network, the ease of installation, the deterioration of the material with the passage of time, its loss of load, the availability on the market of the necessary accessories or the energy optimisation itself.

Oriented PVC is positioned as an outstanding alternative for transporting water in irrigation networks, offering a unique combination of advantages that make it an attractive option for modernising or transforming existing irrigation systems. And TOM® pipe as one of the best options on the market thanks to guaranteeing the advantages of Class 500 in the widest range of diameters and nominal pressures to create strong, durable and sustainable networks that ensure the efficient use of every last drop of water for the agricultural sector.

Some of the outstanding characteristics of the TOM® PVC-O pipes for which this material was prescribed are:

- Their laminar structure is resistant to impacts and crack propagation, significantly minimising breaks during installation and facilitating handling in the rural environment.

- Their low roughness on the inner surface reduces load losses and the energy costs of water transport, optimising the investment of the irrigation community.

- Their chemical inalterability makes the pipes immune to corrosion and highly resistant to fertilisers and phytosanitary products used in irrigation networks.

- The ease of installation thanks to the lightness and jointing system reduces the requirements of heavy machinery for installation and the risk of accidents.

- The significantly lower environmental footprint than other products makes it one of the most environmentally friendly solutions.